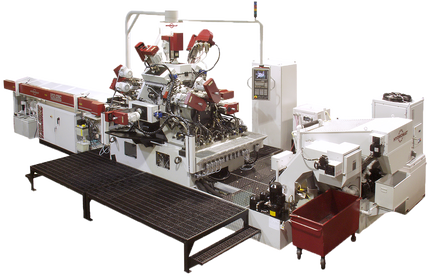

NOVA TCB Recently Invested Millions of Dollars in New Tooling - Achieves Precision Leading Standards That Affords Customers New Parts and Products with More Efficient Throughput

|

There are choices and history shows NOVA will work to earn their customers' trust and business.

|

When one of NOVA’s large bearing customers requested the company supply bearing segments eight years ago, NOVA listened to the need and began research. At the time NOVA was using the tried and true industry standard conventional screw machines that couldn't output the volume, or meet the new goals for tolerances and precision called for by management’s manufacturing objectives.

NOVA successfully achieved the precision goals after retooling their machine lineup, but customer demands for new precision parts outpaced order entries and production volume for precision parts with the new processes. More tooling was added to successfully meet the increasing demands. NOVA just recently added to its tooling lineup, investing in a new trunnion machine that simultaneously produces two parts reducing cycle times from 29 seconds to just four seconds further exceeding standards for output precision and quality. |

NOVA TCB USA manufactures high-precision bearings, agricultural parts and automotive tubular products. NOVA TCB also has manufacturing facilities where resident engineers and quality teams ensure the maintenance of standards and precision of the parts are in total compliance of our customers requirements and high expectations.

Nova can additionally offer the following Value Added Services.

Nova can additionally offer the following Value Added Services.

- All product received into Nova's warehouse is subjected to sampling plans developed in conjunction with the customer's requirements and Nova's quality assurance procedures.

- An on-site inspection lab is utilized to verify incoming product. Delays from the use of off-site inspection sources are typically avoided.

- A full-time technical staff is available to assist you with technical questions and/or concerns.

- Nova typically warehouses 6-8 weeks of stock in its facility. This alleviates the risk of delayed shipment which is unfortunately common when dealing with offshore entities.

- Nova certifies its manufacturing facilities via repeat on-site visits throughout the year and contracts with its strategic partners.

- Level III PPAPs are typically provided for all components that Nova manufactures and provides.

- Nova encourages its customers to visit its manufacturing facility in Powell, Tennessee, as well as their offshore facilities.

- Nova actively pursues continuous improvement in their processes and capabilities in an effort to enhance customer satisfaction.